Services

Die Head Refurbishment Services

– Precision Cleaning, Surface Strengthening & Hardening

We offer advanced diehead refurbishment designed to restore tooling to peak performance and extend its operational life. Through a combination of precision disassembly, pyrolysis cleaning, surface strengthening coatings, and PVD hardening, we ensure your die head performs like new or better.

Whether your die head suffers from wear, polymer buildup, corrosion, or dimensional inaccuracies, our refurbishment process delivers consistent, reliable results.

Why Choose Our Die Head Refurbishment Service?

✔ Deep cleaning with pyrolysis for complete polymer removal

✔ Strong protective coatings for long-lasting tool performance

✔ PVD hardening for superior durability

✔ Cost-effective alternative to buying new die heads

✔ Improved product quality and flow consistency

✔ Extended tooling lifespan and reduced downtime

Electropolishing

Professional Electropolishing Services

– Superior Surface Finishing for Maximum Performance

We provide high-precision electropolishing services designed to improve surface quality, enhance corrosion resistance, and deliver a flawless, high-gloss finish. Electropolishing removes the top microscopic layer of metal through a controlled electrochemical process—creating an ultra-smooth, clean, and hygienic surface that meets the highest industrial standards.

Whether you need electropolishing for medical devices, pharmaceutical equipment, stainless steel components, food processing machinery, or precision-engineered parts, our advanced process delivers consistency, purity, and superior performance.

What Is Electropolishing?

Electropolishing is an electrochemical metal finishing process that

removes imperfections, burrs, contamination, and microscopic high points from

the surface.

The result:

A cleaner, smoother,

mirror-like finish

Enhanced durability and corrosion resistance

Improved part performance and cleanliness

Thermal Cleaning & Pyrolysis Oven

The VACUCLEAN 1713‑XXL is a large‑scale vacuum pyrolysis cleaning system designed to remove adhered organic contamination (plastics, polymers, coatings) from large metal parts, molds, tools and components.

Because it works under vacuum and uses controlled heating (melt‐off, pyrolysis, oxidation)

it is gentle and repeatable, protecting sensitive tools and large assemblies

from damage while maintaining high cleaning performance.

Typical applications include cleaning of large film/blown film dies, non‑wovens

equipment, extruder barrels, large molds, etc.

· Part Diameter: Up to 1.6 meters

· Part Weight: Up to 12,500 kg

· Loading: Front-loading system

· Ideal for: Blown film dies, spin packs, filter bundles

DLyte 500

– Efficient and Automated Electrolytic Polishing

DLyte 500 is an advanced machine for electrolytic polishing of metal components. It combines high precision, repeatability, and superior surface quality with minimal manual handling. The machine is designed for companies seeking mirror-like, functional finishes quickly, safely, and cost-effectively.

Perfect Surface Finish for Industrial Applications

DLyte 500 uses a dry electropolishing technology, providing a smooth, pore-free surface without altering part dimensions. The process removes microscopic imperfections and enhances both corrosion resistance and aesthetic appearance.

The machine is suitable for a wide range of metals, including:

Stainless steel (AISI 316L, 304, etc.)

Cobalt-chrome and titanium alloys

Precious metals such as gold, silver, and bronze

High Capacity and Easy Integration

DLyte 500 is designed for medium to high-volume production, capable of processing multiple parts simultaneously. It can be easily integrated into existing production lines and features a user-friendly interface, making the process consistent and easy to monitor.

With DLyte 500, you get an automated, precise, and sustainable solution for electrolytic polishing. Ideal for companies in medical technology, jewelry manufacturing, aerospace, and automotive industries, where high surface quality and repeatable results are critical.

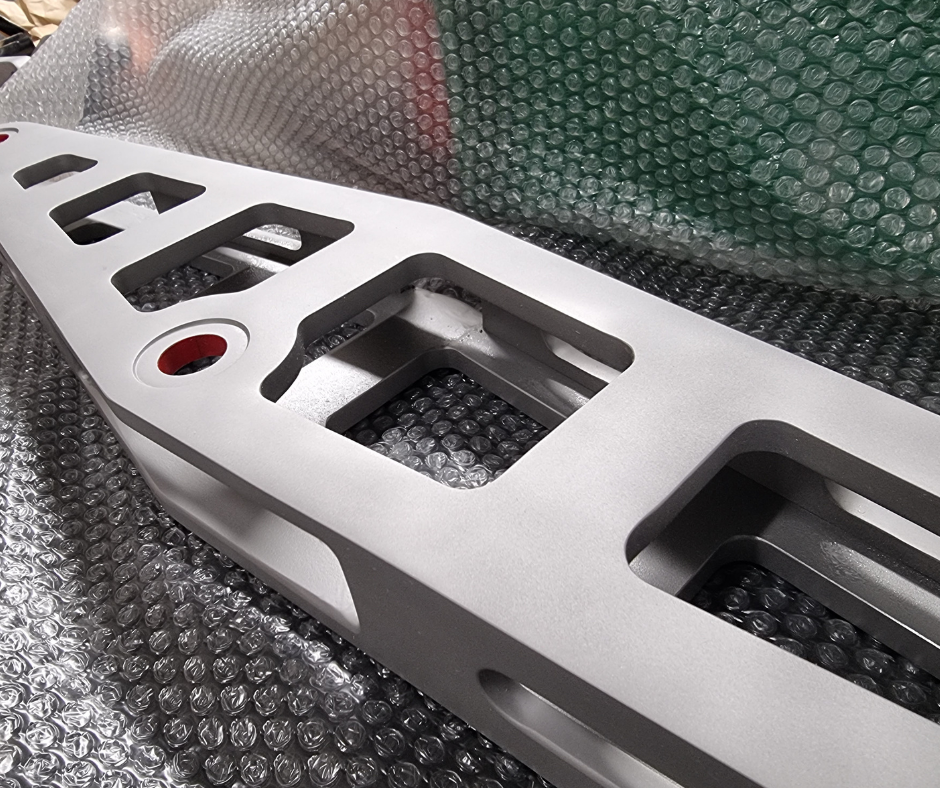

UMC 1250 5-Axis CNC Milling

– Precision from Concept to Finished Component

Our UMC 1250 5-axis CNC milling machine enables us to produce highly complex and precise components with exceptional efficiency and surface quality. Its simultaneous 5-axis movement allows machining of intricate geometries, undercuts, and contoured surfaces in a single setup reducing production time and minimizing errors.

With this advanced machine, we can handle both prototyping and full-scale production for industries such as automotive, aerospace, marine, tooling, and engineering. It is particularly suited for parts that demand tight tolerances, smooth finishes, and high structural integrity.

Key specifications and capabilities:

- Travel X/Y/Z: 1270 / 1270 / 850 mm

- Table load: up to 1000 kg, accommodating large and heavy workpieces

- Spindle speed: up to 12,000 RPM for precise cutting of metals and alloys

- Simultaneous 5-axis machining for complex shapes and multi-surface components

By combining advanced 5-axis technology with our expertise, we deliver parts that meet the highest industry standards — from raw material to finished, ready-to-use components. This ensures maximum accuracy, efficiency, and surface quality for every project.

Mechanical Polishing Services

– High-Precision Surface Finishing for Metal Components

We provide professional mechanical polishing services to enhance the surface quality, appearance, and performance of metal components. Using advanced polishing equipment and skilled technicians, we deliver smooth, uniform, and high-gloss finishes suitable for industrial, hygienic, decorative, and high-performance applications.

Our mechanical polishing process removes scratches, weld marks, imperfections, and surface contamination leaving your parts clean, refined, and ready for coating, electropolishing, or final use.

What Is Mechanical Polishing?

Mechanical polishing is a physical surface finishing method that uses abrasives, polishing wheels, and buffing compounds to smooth and refine metal surfaces. It is ideal for preparing components for further treatment or for achieving a visually flawless finish.

-Benefits of Our Mechanical Polishing Service

✔ High-Gloss, Smooth Surface Finish

We achieve a uniform, mirror-like finish that enhances both appearance and functionality.

✔ Improved Cleanability & Hygiene

Smoother surfaces prevent contamination buildup—ideal for food, pharma, and medical industries.

Bead & Glass Blasting Services

– Clean, Uniform, and Precisely Finished Metal Surfaces

Achieving a flawless metal surface starts with a controlled and consistent preparation process. Bead and glass bead blasting are highly effective methods for removing surface impurities, discoloration, weld residues, and light corrosion while maintaining the integrity of the base material. This finishing technique creates a smooth, satin-like appearance and is suitable for applications requiring both functional and aesthetic improvement.

Our blasting process ensures a uniform texture, improved cleanliness, and an ideal foundation for further treatments such as coating, electropolishing, mechanical polishing, or PVD hardening.

PVD Coating Services

– High-Performance Surface Hardening and Wear Protection

Enhancing the durability and performance of metal components begins with a high-quality surface treatment. PVD (Physical Vapour Deposition) coating provides an exceptionally hard, smooth, and wear-resistant layer that significantly improves tool life, reduces friction, and protects against corrosion. This advanced vacuum-coating process is ideal for precision parts, tooling, stainless steel components, and surfaces exposed to demanding environments.

Our PVD coatings deliver consistent quality, long-term durability, and excellent aesthetic appeal

making them the perfect choice for industries requiring both performance and reliability.

✔ Extreme Surface Hardness

Creates a highly durable surface that withstands wear, abrasion, and mechanical stress.

✔ Reduced Friction & Improved Sliding Properties

Ideal for moving parts, tooling, and components where low friction is essential.

✔ Superior Corrosion Resistance

Protects metals from moisture, chemicals, and oxidation.

✔ High Temperature Stability

Maintains hardness and integrity even under elevated temperatures.

✔ Enhanced Aesthetics

Offers a clean, smooth, and decorative finish available in multiple colors (e.g., gold, black, silver, chrome-like).

✔ Environmentally Friendly Process

PVD is a clean, vacuum-based coating method with no toxic waste or harmful chemicals.

Total Solutions Services

– From Part Manufacturing to Final Finishing

Delivering high-performance components requires a fully integrated approach—from the initial manufacturing of a part to the final finishing process. Our Total Solutions Services cover every step of the production and refinement chain, ensuring precision, consistency, and maximum durability. With a complete in-house workflow that includes machining, cleaning, polishing, surface treatment, coating, and quality inspection, we provide reliable, end-to-end solutions tailored to your application.

This all-inclusive service eliminates the need for multiple suppliers, reduces lead times, lowers costs, and guarantees uniform quality from the moment a part is produced to its final delivery.